We interviewed Coverguard’s sustainability team on why they chose Carbonfact, practical tips on the selection process, and the onboarding experience with Carbonfact.

Coverguard specializes in the Personal Protective Equipment (PPE) market, and the company provides head-to-toe in different working environments globally - from the Middle East, Africa, and to Europe.

With a strong Corporate Social Responsibility (CSR) strategy focused on 2030, Coverguard has identified five main pillars to guide its approach: circular economy, environment, ethics and sustainable procurement, human management, and strong partnerships.

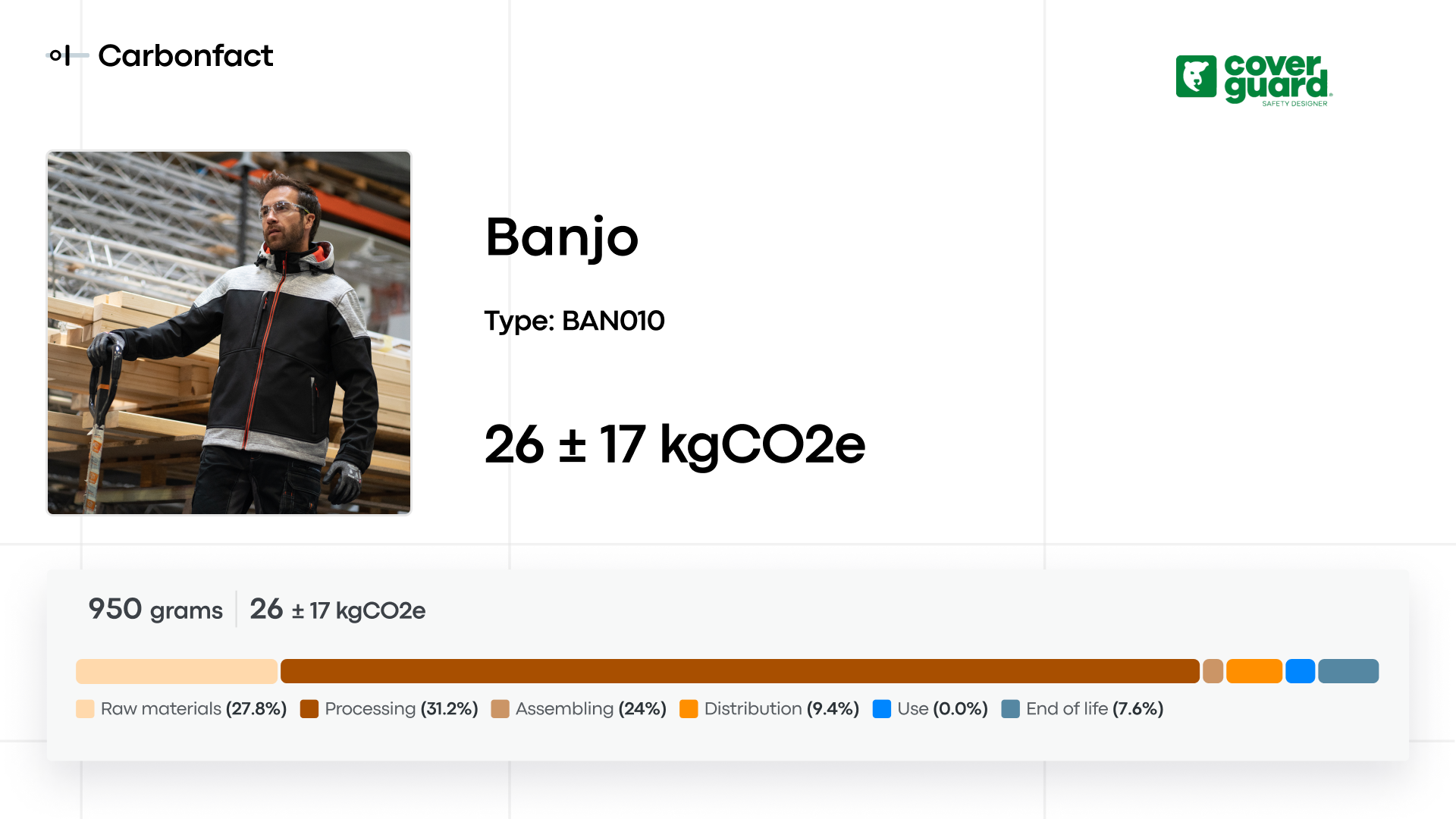

Carbonfact, a Carbon Management platform tailored to the needs of apparel and footwear brands, is helping Coverguard navigate its journey towards decarbonization.

In this interview, we sat down with Juanita Toro Giraldo, Coverguard’s product CSR manager, and Claire Wagret, corporate CSR manager, to learn more about how Carbonfact’s features strengthen the brand’s CSR strategy.

Interview with Juanita Toro Giraldo, CSR Manager & Product Garments Manager at Coverguard

“From the start of our collaboration with Carbonfact, we started showing our clients what we were doing. For example, Crabonfact’s visualisation tool for DPP was really important in proving that we have a partner with a good data strategy, helping with our CSR strategy. It really helped us to secure our business and sell more products at the end. We are working with B2B clients, and I love the fact that we can export DPP links or even QR codes in Carbonfact.”

Why did you start looking for a Carbon Management solution?

Most of our clients are B2B, who themselves are developing strong CSR strategies to stay compliant with regulations and, therefore requesting information about where the products are coming from and their impact.

In the workwear industry, most emissions are generated during the manufacturing process, so we needed to understand the entire supply chain to make meaningful changes. While we had already established direct contact with our Tier 1 suppliers, we lacked detailed insights into the origin of raw materials and the sub-contractors involved.

How did you find Carbonfact?

We were in search of a company that could map our supply chain, conduct a Life Cycle Analysis (LCA) for all of our products - which is the first step of ecodesign - and measure our carbon footprint.

We had previously worked with a consultant who had performed LCAs for our three main products, but it was a costly and time-intensive process that resulted in a PDF with complex data that was difficult to understand and use in practice.

With new regulations in France becoming more and more relevant for our textile products, we decided to search for a well-recognized solution for traceability and LCA.

However, during our search, we realized that we needed separate tools that were best in their respective sectors (traceability and LCA) and could address multiple aspects of our Corporate Social Responsibility (CSR) goals, such as traceability, measuring our carbon footprint, and setting SBTi targets.

In the end, we decided to choose Trace for Good (traceability) and Carbonfact (LCA and carbon footprint). Read more about Coverguards traceability solution selection here.

Why did you choose Carbonfact over the alternatives?

Carbonfact checked all our boxes because it focuses on the apparel industry, and is a certified company with very strong positive feedback from clients, and adheres to the GHG protocol, ISO standards, and the European Commission's PEF standard.

The platform is really intuitive, with easy-to-comprehend reports and graphs that all our development and design teams can access.

Additionally, Carbonfact was also able to provide a direct connection to our systems, for example, we use Trace for Good to collect more information about our suppliers, and the automated connection between Trace for Good and Carbonfact will provide live data and reduce uncertainty of our product footprints. This partnership will help us advance quickly in the data collection process.

An additional important factor was that Carbonfact was the only solution that was able to calculate product-level footprints for our complete catalog, which has a variety of products apart from textiles including working shoes, gloves, helmets, etc.

Another important point was the fact that everyone at Coverguard who had contact with Carbonfact’s team during the selection process felt like they really wanted to create something together and be part of a long-lasting partnership, rather than focus just on profit.

If you could give any advice to others going through the selection process for a Life Cycle Assessment Software - what would it be?

Either you can do LCA with a consultant which will be a time-consuming expensive project and you might end up with LCA for a few products that you cannot modify, do simulations with, and is hard to comprehend, or you can go for a scalable solution with a very practical platform, which can analyze all of your products, and help you to build a decarbonization path with everyone inside your company. It should be easy to use for your sustainability team, development team, and designers.

It is also important to know your needs. Our requirement was not just to comply with regulations, as only a part of our products were subject to textile laws, but to truly understand our products better, therefore we chose a partner accordingly.

Last but not least, you will never find a platform that will be best at everything, therefore you need to search for the best of the market in something specific, that is why we ended up picking two platforms - Trace for Good and Carbonfact.

How did the onboarding process go, how long did it take, and what were the steps involved?

I was impressed with how Carbonfact handled the integration of our product data, despite it not always following the same pattern across all of our products.

Our team only needed to send all the data to Carbonfact, and they took care of the rest. The time investment on our side was minimal - It was a one-hour kickoff meeting with Carbonfact, followed by a one-hour meeting between our data teams and an additional meeting for instructions from our team… and 25 minutes to send all the data that we had.

Carbonfact was able to use all of our data from the beginning, they cleaned and normalized our data, filled in our data gaps, and in just one week we already had the first version of our data on the platform, which I experienced as extremely fast.

Something that we also really like is that we constantly discuss with the team how we would like to have our data displayed on the platform. For example, we can add custom filters to the dashboards for our collections.

In only two months, most of the LCAs of all of our products are already done, and now we can focus on reducing uncertainty.

How has your work changed now with Carbonfact?

In our 2023 CSR strategy, we defined five projects for 2024, one of which involves incorporating more recycled materials into our products.

Through the use of Carbonfact's product simulation tools, we have demonstrated that adding certified recycled materials can significantly reduce the carbon footprint of this product.

This tool not only makes it easier for us to communicate these initiatives to our clients but also provides internal proof that the project is effective.

It is important to note that the LCA tool is essential in providing scientific evidence to support our environmental claims and prevent any form of greenwashing. For instance, in our previous communication on products and CSR, we avoided using the term "ecodesign" due to lack of proof. However, with the help of Carbonfact, we can now use this term with confidence since we have the evidence to back it up.

What are your next steps? How are you using the simulation tools?

We have launched four different projects in the field of circular economy.

The first project is about having an LCA platform and working with Carbonfact.

The second project involves the use of certified recycled materials, and we will utilize Carbonfact to assess the effectiveness of the project. For example, we simulated that if we replace the raw material of one product into GRS-certified material, we can reduce 3kgCo2e.

Another project is to decrease the impact of our packaging and of course Carbonfact will be the key tool to prove that we can decrease our footprint by changing how the packaging looks.

Additionally, it is essential to measure carbon emissions, and Carbonfact will help us advance our sustainability strategy, such as by establishing SBTi goals.

We look forward to having long-term partnerships with Carbonfact and Trace for Good, and growing together.

Lidia Lüttin

Lidia Lüttin