Environmental data platform - built for apparel and footwear brands, and their suppliers.

Carbonfact's methodology:

Scope and Life Cycle Assessment (LCA) Methodology:

For this Digital Product passport, we conducted a comprehensive Life Cycle Assessment (LCA) of the textile product, encompassing all critical phases from cradle to grave. Our methodology is compliant with the ISO 14040-44 standards, and we are currently adjusting to the latest iteration of the Product Environmental Footprint Category Rules (PEFCR) draft for footwear and apparel. The life cycle stages covered in this assessment include:

- Raw Material Extraction and Production: This initial phase involves the extraction and processing of raw materials. For natural fibers, it includes agricultural activities such as planting, cultivation, and harvesting. For synthetic fibers, it encompasses the extraction and processing of petrochemicals.

- Textile Material Production: This phase involves the processing of raw materials into textile fibers and finished components. It includes activities such as spinning, weaving, dyeing, and finishing, transforming raw fibers into fabric or other textile forms (commonly referred to as tier 2).

- Manufacturing: This stage covers the assembly of textile materials and components into finished products. It involves cutting, sewing, and other processes required to produce the final textile goods ready for the market.

- Packaging: The packaging phase involves the materials and processes used to package the finished textile product for distribution and sale. This includes primary, secondary, and tertiary packaging materials.

- Distribution: This stage addresses the transportation and logistics required to move the textile products from the manufacturing site to various distribution points and ultimately to the consumer.

- Use: The use phase includes the consumer utilization of the textile product, covering the lifespan of the product in regular use. It considers factors such as washing, drying, and maintenance activities.

- Recycling processes: We use the "cut-off" approach placing the burden of the recycling treatment on the material's secondary life. Consistently, for materials with recycled content, we include the recycling treatment processes and exclude the previous life of the virgin material. This method is chosen for its simplicity, intuitive understanding for customers, and a strong incentive for brands to use recycled materials.

- End of Life: This final phase deals with the disposal or recycling of the textile product once it has reached the end of its useful life. It includes waste management practices such as landfill and incineration.

Data sources

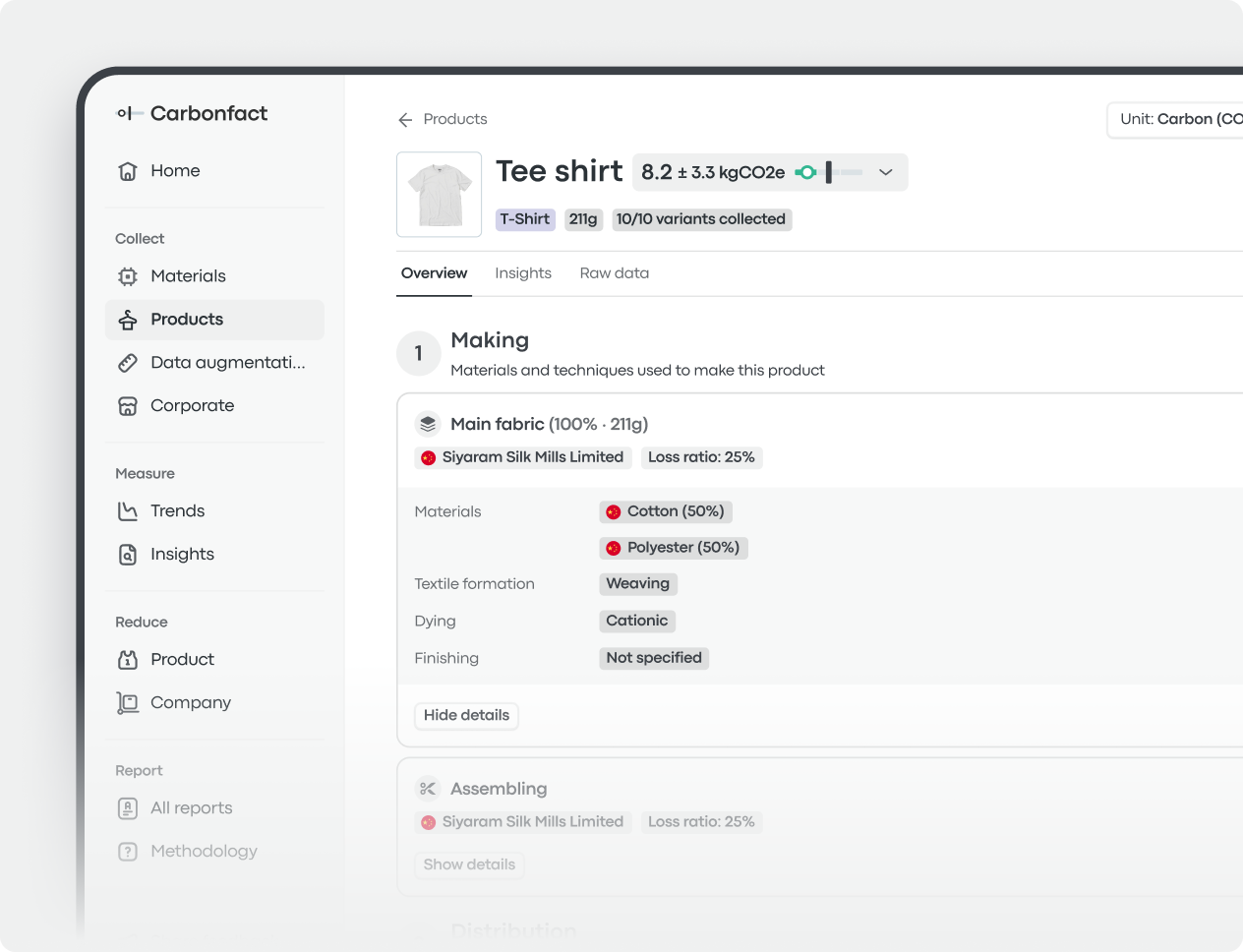

We collected detailed primary data including general product information (SKU, category, care label, name, mass, and image URL), purchase orders (SKU, order dates, units ordered and delivered, supplier details, shipment origin and destination, and transport methods), and bill of materials (SKU, component names, material types, importance, mass, and loss rates). Additionally, we gathered data on materials (composition, supplier names, and locations), packaging (elements and composition), supplier energy consumption (supplier, year, energy type, amount), and sales (SKU, date sold, quantity).

Industry-specific data included fabric details (width, yield, density, linear density, formation, dyeing, printing, and finishing methods) and leather specifics (thickness, GSM, roll width, cutting and assembly loss rates, and animal source) as well as material loss rates during various stages of production.

In terms of secondary data, we utilized the Environmental Footprint (EF) 3.1 dataset, Ecoinvent 3.10, and recent scientific publications for various processes involved in the textile product lifecycle.

Limitations

If we lack information about specific steps, we determine the minimum and maximum values from our different data sources.

The model uses the median value from this range, and we highlight the uncertainty this missing information introduces. In some cases, we also use heuristics built from data collected across customers to fill certain data gaps.

About Carbonfact

An environmental sustainability platform built for specifically

apparel and footwear brands and manufacturers.

Product impact measurement

Environmental reporting (CSRD, DPP, CDP)

Corporate emissions calculation (GHG Protocol)

Simulation tools for eco-design

CHOSEN by Hundreds of BRANDS AND SUPPLIERS