Environmental data platform - built for apparel and footwear brands, and their suppliers.

Practical Buyer’s Guide with detailed comparisons of consultants, generic platforms, and industry-tailored solutions.

December 22, 2023

This comprehensive analysis of the carbon footprint of different printing techniques was created by Dr. Bahareh Zamani, Carbonfact's Head of Science. Explore our blog if you want to read more research from our climate, data, and fashion experts.

Textile production is a major source of water pollution, with dyeing and finishing processes accounting for an estimated 20% of global freshwater contamination.

As a result, some fashion brands are exploring alternative methods of coloring their products, such as screen and digital printing. While digital printing offers advantages over traditional dyeing methods in terms of water and chemical usage, it’s not without environmental drawbacks. For instance, the electricity required to power digital printers contributes to its carbon footprint.

Curious about the carbon footprint of different printing and dyeing techniques? We've analyzed the carbon footprint of screen printing, digital printing, and fabric dyeing to provide you with a clear understanding of their hotspots.

We hope the information will help you make more informed decisions about your printing and dyeing practices, allowing you to take steps to decarbonize your supply chain. For those unfamiliar with the dyeing and printing methods, here's a brief overview of each technique:

Screen printing is a traditional printing method that involves forcing ink through a stenciled screen onto fabric. It's a versatile technique that can create a wide range of designs, from simple text to intricate patterns. Screen printing is often used for small to medium-sized production runs.

Digital printing is a more recent printing method that uses inkjet technology to apply ink directly onto fabric. It's a quick and efficient way to print high-resolution designs, including photographs and complex patterns. Unlike screen printing, which requires preparing screens for each color, digital printing allows for multicolor designs without the need for multiple screens. Disadvantages of digital printing include color bleeding, higher ink costs, and reduced washability as the color can fade away easily.

Fabric dyeing involves immersing fabric in a dye solution to color the entire fabric. Traditional dyeing methods involve immersing fabrics in dye solutions containing synthetic or natural dyes. These dyes penetrate the fabric's fibers, permanently changing the color, making it a common method for producing solid-colored fabrics.

Before we dive into the carbon footprint of each printing and dyeing technique, it’s important to establish a clear boundary. This outlines the specific steps involved in each process, ensuring a consistent and accurate assessment of their carbon footprint. By defining the boundary, we can accurately quantify the energy and material consumption of producing 1 kg of printed or dyed fabric.

Let's dig into the boundaries for each process:

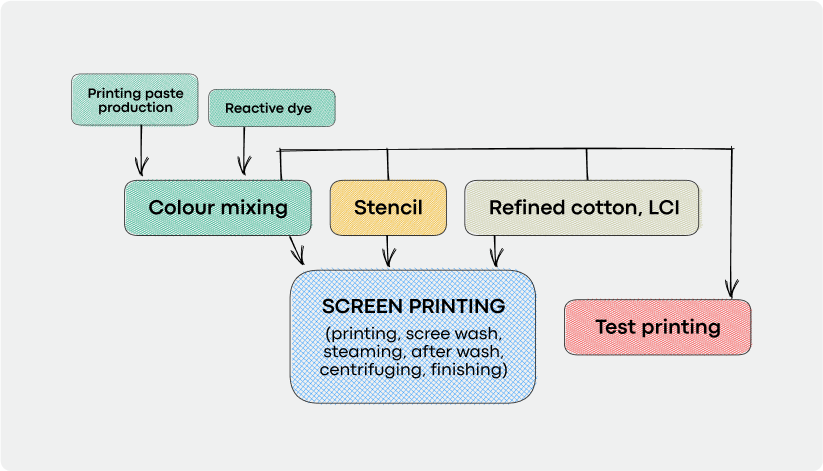

The screen printing process involves three main materials: the printing paste, reactive dye, and the stencil for the pattern. To begin, the reactive dye and printing paste are mixed together.

Next, several test prints are made to ensure the desired results before proceeding with the main printing process.

Once the main screening is complete, the dye residue is washed away, followed by centrifuging, steaming, and finishing to ensure the final product meets the desired quality standards.

Similar to screen printing, reactive dye, and paste color are needed to create vibrant fabric designs. Before printing, the fabric undergoes a pretreatment step to ensure optimal dye adhesion and color fastness. After printing, the fabric goes through a series of post-printing treatments: washing, centrifuging, steaming, and finishing.

.png?width=823&height=471&name=Printing%20(1).png) Adapted from Marjukka Kujanpää et al., 2014

Adapted from Marjukka Kujanpää et al., 2014

Similar to printing, dye material is essential for the dyeing process. The fabric is placed inside a tubular system and submerged in a dye bath during this process. Once the desired color is achieved, the fabric is squeezed through rollers to remove excess dye liquor.

.png?width=823&height=470&name=Printing%20(2).png) Adapted from Marjukka Kujanpää et al., 2014

Adapted from Marjukka Kujanpää et al., 2014

To establish the carbon footprint for 1 kg of fabric with a GSM of 200, we used the scientific paper* ‘Environmental performance of future digital textile printing’ (Marjukka Kujanpää et al., 2014) as our baseline. We assumed all processes would happen in Europe using the European electricity grid mix.

*Note: In the original scientific paper, the carbon footprints for the printing processes were calculated for 750 m2 fabric.

The base case scenario results are as follows:

.png?width=823&height=471&name=Printing%20(3).png)

Digital printing boasts a significantly lower carbon footprint compared to screen printing. To understand why, let's identify the steps that contribute the most to the overall carbon footprint of each technology.

The table below illustrates the percentage contribution of each step. The results reveal that the primary contributors to screen printing's carbon footprint are the test drive and after-wash phases. Both these steps demand higher energy consumption for screen printing than digital printing.

In comparison, digital printing generates approximately 2 kg CO2e per kg of fabric less than screen printing. This is primarily attributed to screen printing's higher energy requirements for washing and intermediate testing, which is unnecessary for digital printing.

Digital printing vs. screen printing (Europe)

We also compared the results of digital and screen printing across three geographical regions: Europe, Vietnam, and China. The carbon footprint associated with each printing method is influenced by the carbon intensity of the electricity grid in each location.

The findings reveal that in countries with a higher carbon footprint electricity mix, such as China, digital printing can lead to substantial carbon emission savings of up to 7.8 Kg CO2/ Kg fabric.

Digital printing vs. screen printing (different locations)

So when choosing between screen and digital printing, digital printing is the less carbon-intensive choice, regardless of where you manufacture your products.

Now that we've established digital printing has a lower carbon footprint than screen printing, let's compare its environmental impact to fabric dyeing. By analyzing the Base Empreinte database, we found the following results for the carbon footprint of the dyeing process:

.png?width=823&height=471&name=Printing%20(4).png)

The comparisons indicate that digital printing can reduce carbon emissions by up to ~1 kg CO2e per kg of fabric compared to traditional dyeing methods. That’s because the dyeing process is heat intensive.

While the carbon footprint result for printing was reported for 1 m2 of fabric, assuming the same footprint applies for higher GSM fabrics, the carbon savings benefits of digital printing can reach approximately 2.6 kg CO2e compared to dyeing.

Digital printing vs dyeing: Source of energy matters

To calculate the carbon footprint of the dyeing process precisely, one of the important data points is the heat source. In non-European countries, where coal or natural gas are common heat sources, dyeing emerges as the preferred method, as the carbon footprint associated with heat generation from these sources is lower than that of electricity grids in these regions.

To decarbonize the dyeing process, factories can switch to low-carbon heat fuel methods, such as biofuel, heat pumps, or solar thermal water heating. These systems are part of efforts to reduce carbon emissions in the heating sector and transition to more sustainable energy sources.

Carbonfact is the only fashion-specific Carbon Accounting and Product-LCA platform that helps brands and manufacturers discover the exact sources of their environmental impact and take actionable steps to reduce their footprint. With the Carbonfact tool, you can run detailed and accurate life cycle assessments (LCAs) in a fraction of the time and cost of traditional methods. From key emission drivers across the value chain to product design decisions, our platform provides the insights you need to lower your environmental impact.

Book a 1:1 demo with a member of the Carbonfact team to find out more.

We base our findings on the scientific paper “Environmental performance of future digital textile printing, Marjukka Kujanpää et al. , 2014” and BaseImpacts database for dyeing process.

© 2026 Kanso, Inc. All rights reserved.

If you click on “Accept all” you agree to the use of these cookies. To find out more about the cookies we use, see our Privacy & Cookie Policy. Or, you can continue without agreeing .